Building a 3D Printer

For a while now I’ve been working to upgrade my toolset, in order to make more interesting robots. One of the projects is 3D printing. Today I’m happy to report the completion of a milestone: I am the proud owner of a home-built 3D printer!

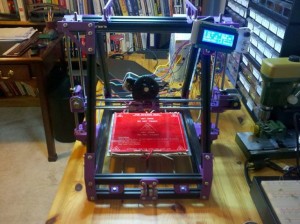

My MendelMax 3D Printer. At this point it was 90% done; I have since added lights and tied up the wires.

There are so many choices when it comes to 3D printers, that I was nearly paralyzed in moving forward on the project. Then one day the Nova Labs 3-D printing group announced a group build. For $750 we would get the parts for a $2,000 printer (a variant of the MendelMax 1.5), and assemble it ourselves with help from the group. I hesitated a bit — I suspected the build might be rather involved — but I also knew that, claims from MakerBot notwithstanding, there really is no such thing as a great “out of the box” 3D printer. If you want your printer to do well, you have to know how the machine works, and getting your hands dirty is the best way. Having expert guidance was a significant bonus.

So I joined in, and after the usual delays of hackerspace group buys, we started building. I was a little dismayed to find there were no written directions at all! Just a few YouTube videos for a related model, which only covered the hardware part of the build. That meant I had to come in to Nova Labs on Monday or Tuesday to join the build group; I couldn’t do much at home. Sometimes this was inconvenient, but I got to know some great people, all of whom were extremely helpful. Brian Briggman in particular went out of his way to show up at every build meeting and helped dozens of us complete our printers.

There were some difficulties along the way. Some of the frame pieces, being custom, either didn’t fit right at first or needed slightly longer screws. Then I screwed in the RAMPs board too tightly, causing a short — this did not cause permanent damage, fortunately. My first print was a little hairy, as the hot end thermistor had quietly detached itself, and we were therefore heating up the PLA until it smoked. As I was the first person to try printing with PLA, we didn’t know that wasn’t normal! (After that I went through and added strain relief to every wire.)

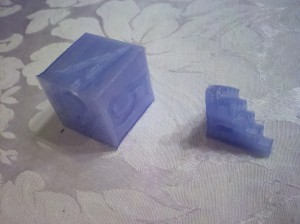

But after the thermistor adventure, I got some successful prints almost immediately — and this is without calibration. Here is a picture of my Futura die, and a 5mm calibration cube pyramid:

I have some work left to do. The printer bed is (pretty much) level now, thanks to some washers. I need to confirm the x and y stepper motors are moving the right distance per step. Then the extrusion rate must be calibrated, and this varies with different filaments, so will need to be done many times in the future.

In many respects the biggest challenge is software. If I want to go beyond printing items off of Thingiverse I must learn to to design my own objects. There are many programs for doing 3D CAD design, but one must take the time to learn how to do it, and the options for hobbyists are generally not user friendly. I’ve looked at a few. (It’s worth mentioning here that I found an outstanding free 2D software CAD program, DraftSight. I am told it is a clone of AutoCAD.)

After the 3D design is done, it’s often necessary to manipulate the files to get them to work properly for printing. So I am also learning about slic3r, netfabb, and Repetier-Host.

Lots of fun ahead!

Hi!

Are you satisfied with your 3D printer, or would you have choosen differently based on your experience now?

Cheers

Paul

I am happy with it, that said I have not yet put it to heavy use or have much else to compare with. Getting to know the other people in the build group has been great. Without that, I would likely have gotten a pre!ssembled model.

I am in NL BG6 and I am pulling my hair! Based on what I have read here on your website and what I have heard about the past NLBGs my experience is on the edge of chaos! I understand that achievements come with twice as many or a greater number of failures. I thought we were going to build the T-Max, but we are building a Graber-Prusa I3 3D Printer for the cost of $550.00. I was informed that it is less complicated than the T-Max, but it is very, very challenging when we are building a 3D printer without any detailed instructions and missing parts [I am learning that might be the premise of Maker Space, Hacker Space and Open Source]; however, for a noob like me it is a monumental task (ARGH!). I have learned a lot, but regardless of anybody’s level of experience in any technical project communication is very, very important. As the Captain in Cool Hand Luke said to Luke, “What we’ve got here is failure to communicate”, so do I need to participate in at least three build group projects to get my mind right? Reference: “You run one time, you got yourself a set of chains. You run twice, you got yourself two sets. You ain’t gonna need no third set ’cause you’re gonna get your mind right. And I mean RIGHT. (To the other inmates) Take a good look at Luke. Cool Hand Luke?” I am trying to learn the parts, so I could identify the parts because our build group is closer to having a pile of parts and a few tools dumped on a table and being shown a photo of the completed 3D printer and told “turn this pile into this 3D printer”! We have instructions, but for my level I may need ten steps in between the build group’s step 1 and step 2. The Build Group Leader is very intelligent, but has a different method of communicating that causes a lot of frustration – kind of like young grasshopper learning to snatch the pebble from the Master Po’s palm. I am thankful for the opportunity to build a 3D printer, but I really thought the BG6 would be more collaborative between the Leader and Fellow Members. It is kind of like a race and the attitudes have changed dramatically from day 1. When I explained to the BG6 Leader that there was daisy chain effect of BG6 members borrowing or stealing parts from other members either because their parts were missing or each member lost a part on the dark carpet and has lead me to a greater number of members with a parts shortage.

John, I’m sorry to hear about the difficulties you are experiencing. Yes, it is definitely a challenge. The T-Max runs almost $2k (I believe) so you are saving a fair bit. It is a good idea to find people with spare parts, no matter what project you are on!